海洋输水用大口径螺旋钢管承受压力极限

称外径 mm

壁厚mm 静水压试验压力 单位:MPa 1MPa约等于10公斤

SY/T5037-2000 GB/T9711.1-1997

Q235B 16Mn Q235B L360

219 6/7/8 7.7/9.0/10.3 11.3/13.2/15.1 10.9/12.8/14.6 14.8/17.3/19.7

273 6/7/8 6.2/7.2/8.3 9.1/10.6/12.1 8.8/10.2/11.7 13.5/15.7/17.9

325 6/7/8 5.2/6.1/6.9 7.6/8.9/10.2 7.4/8.6/9.5 11.3/13.2/15.1

377 6/7/8/9 4.5/5.2/6.0/6.7 6.6/7.7/8.8/9.9 6.4/7.4/8.5/9.5 9.7/11.4/13.0/14.6

426 6/7/8/9/10 4.0/4.6/5.3/6.0/6.6 5.8/6.8/7.8/8.7/9.7 5.6/6.6/7.5/8.4/9.4 8.6/10.1/11.5/12.9/14.4

478 6/7/8/9/10 3.5/4.1/4.7/5.3/5.9 5.2/6.1/6.9/7.8/8.7 0.0/5.9/6.7/7.5/8.4 7.7/9.0/10.2/11.5/12.8

529 6/7/8/9/10 3.2/3.7/4.3/4.8/5.3 4.7/5.5/6.3/7.0/7.8 0.0/5.3/6.0/6.8/7.6 7.3/8.6/9.8/11.0/12.2

630 6/7/8/9/10 2.7/3.1/3.6/4.0/4.5 3.9/4.6/5.3/5.9/6.6 0.0/4.4/5.1/5.7/6.3 6.2/7.2/8.2/9.3/10.3

720 6/7/8/9/10 2.4/2.7/3.1/3.5/3.9 3.5/4.0/4.6/5.2/5.8 0.0/3.9/4.4/5.0/5.5 5.4/6.3/7.2/8.1/9.0

820 6/7/8/9/10/12 2.1/2.4/2.8/3.1/3.4/0.0 3.0/3.5/4.0/4.5/5.0/0.0 0.0/0.0/3.9/4.4/4.9/0.0 4.7/5.5/6.3/7.1/7.9

920 7/8/9/10/11/12 2.1/2.5/2.8/3.1/3.4/3.7 3.2/3.6/4.1/4.5/5.0/5.4 0.0/3.5/3.9/4.3/5.2 4.9/5.6/6.3/7.0/7.7/8.5

1020 7/8/9/10/11/12 1.9/2.2/2.5/2.8/3.0/3.3 2.8/3.2/3.7/4.1/4.5/4.9 0.0/3.1/3.5/3.9/4.7 3.8/4.4/5.1/5.7/6.4/7.0/7.6

1220 8/9/10/11/12/14 1.8/2.1/2.3/2.5/2.8/3.2 2.7/3.1/3.4/3.7/4.1/4.8 2.6/2.9/3.3/3.9/0.0 4.2/4.8/5.3/5.8/6.4/7.

海洋输水用大口径螺旋钢管的常用标准一般分为:SY/T5037-2000(部标、也叫 普通流体输送管道用螺旋缝埋弧焊钢管)、GB/T9711.1-1997(国标、也叫石油天然气工业输送钢管交货技术条件第一部分:A级钢管(要求严格的有GB/T9711.2 B级钢管))、API-5L(美国石油协会、也叫管线钢管;其中分为PSL1和PSL2两个级别)、SY/T5040-92(桩用螺旋缝埋弧焊钢管)。

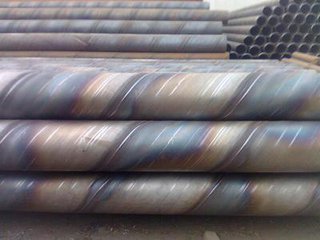

海洋输水用大口径螺旋钢管特点:直缝焊管生产工艺简单,生产效率高,成本低,发展较快。螺旋焊管的强度一般比直缝焊管高,能用较窄的坯料生产管径较大的焊管,还可以用同样宽度的坯料生产管径不同的焊管。但是与相同长度的直缝管相比,焊缝长度增加30~100%,而且生产速度较低。因此,较小口径的焊管大都采用直缝焊,大口径焊管则大多采用螺旋焊。